Originally appeared on zucksrototillers.com, a wonderful resource for any enthusiast.

The whole sense and purpose of the Rotary Tiller is to cultivate the soil more easily and efficiently than the gardener with a digging fork or the farmer with an ox and plow. The tine, of course, is the one part of the machine which justifies its existence. Tines wear out. Tines can break or bend. Tines have different tasks to perform. Some tines work reasonably well in rocky soil while others are reasonably good at turning under green matter. Understanding the importance of tine design and its resulting utility in action is key to seeing the development of tines over the years.

Graphic A – Herr Von Meyenburg – 1916 – Tines were formed from round stock into “S” shaped tools.

The earliest tines appear to have been made to cultivate existing garden soils such as fields where cultivation had been ongoing for some time as opposed to new fields which required removing entrenched sod and the remaining roots of trees and shrubs. The job description for the tine, in this case, was a much easier task than if it had been asked to dig up roots and sod.

Graphic B –Von Meyenburg-1922 – Same tine style as in 1916 – see Graphic A above.

Let’s take a look at some information about early tiller designs so we can see what they can tell us about the part that actually did the digging – the tine. I really lucked out when I found some documents stored in the archives of the Rensselear County Historical society in Troy, NY where they landed after Garden Way Mfg. went out of business in 2000. Looking through boxes of papers, I came across copies of patents led with the U.S. Patent service by two inventors from Switzerland. First out of the the box appeared a patent granted to Herr Von Meyenburg for a “tilling Machine” in 1916! I had no idea that the notion of rotary tilling dated back that far. But, there it is. And please notice the tines; not blades or choppers but obviously implements made from round stock, most likely in the range of 3/8ths to 1⁄2 inch in diameter. (See graphic A) This design would be able to scratch, or cultivate the garden soil without much difficulty, as opposed to working up virgin land with the likelihood of presenting a more difficult challenge.

So, as far back as 1916, the idea of tilling the soil with a machine that featured rotating tines was more than a dream in some inventor’s head; it was a reality. Then, further along in my search, the internet led me to even earlier examples of rotary tillage. Herr Von Meyenburg, we find again, was granted an even earlier patent in 1910. So how far back did this notion of rotary tilling really go? Well, I really have to plead ignorance on this point, but I’m pretty sure we won’t have to go back as far as the prehistoric cave drawings in the south of France.

Graphic C – DuFour 1931 – Early indication of alternate tine styles for use in different types of soils.

But wait! While not exactly prehistoric, “Gardening Beyond the Plow” (put out by Garden Way Mfg.-1981) makes reference to an elephant-sized steam- powered rotary tiller built somewhere in central Europe in 1857 which employed tines clearly made from some form of round stock rather than blades.

Adding to this, we do know that Rototiller entrepreneur, Mr. C. W. Kelsey, who was also an early automotive pioneer, was born in Switzerland of American parents; and was in the business of importing Swiss tillers to Long island, NY in the early 1930’s. Kelsey moved the business to Troy in about 1937 where he commenced the manufacture of Rototillers with the financial help of some Troy businessmen. It now becomes clear that a lot of technology about rotary tillers in general, and tines specifically, originated with some Swiss inventors.

I just can’t help wondering how many different tine designs early inventors had to toss onto the scrap heap of trial and error before they settled on product acceptable to the customer who actually used the tiller. Some later styles, beginning in the ’30s, were designed to chop up garden debris so the plant material would get buried in the soil, while older designs were meant to only lift the soil for aeration and simple seed bed preparation. The success of any design depended on soil conditions and the scope of the particular gardening task at hand. Ask any group of users and you’ll find they all had their favorites.

Graphic D – DuFour –1936 – Different inventor, yet same “wire tine” style as in 1916.

Now, let’s move ahead to 1922 and here’s Herr Von Meyenburg again, with a new patent. (See graphic B) This time we see a machine with attachments to perform other homesteading chores like field mowing. And here again are the same tines as in 1916. If these agricultural implements were getting any field use, we’d have to assume at least some satisfactory user feedback concerning the tines or we’d be seeing a few new tine styles by 1922. But up to this point the only tine styles I have come across are the various “s” shaped round stock tines that we see in Fig 2 of Graphic B above.

But soon different designs for rotary tiller tines began to appear. Take a look at this patent issued to Leon DuFour, also a Swiss citizen, in 1931. It, too, was labeled a tilling Machine by the U.S. Patent of Office. (See graphic C) Here we can see several alternate tine styles. Very interesting! Fig. 4. shows a resemblance to the pick tines on a 1949 Model T Rototiller. and Fig. 5? This resembles the same 1949 Model T’s cultivating tines. Similarly, Figs. 7 and 8 resemble Rototiller Inc.’s “Revolutionary new Roto-Millers” for the same Model T, introduced about 1951 as an optional tine set. (see Graphic L)

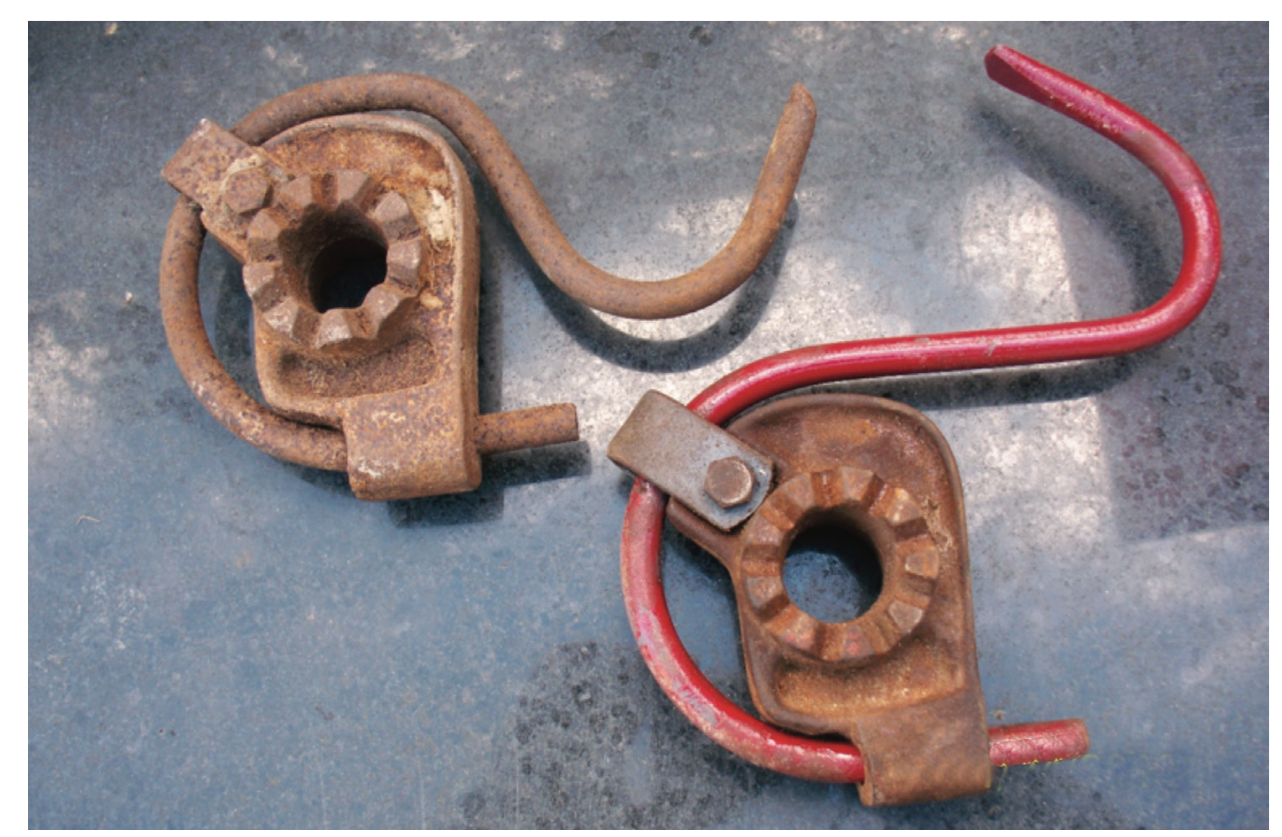

Graphic E - 1937 Rototiller, Inc. Model B1-3 two piece Spring Tine

Graphic F - 1937 Rototiller, Inc. Model B1-3 two piece spring tine w/Booster insert. The extra spring indicates a need for additional tine strength due to different soil conditions.

Mr. Kelsey obviously had working relationships with the Swiss inventors from way back in the Long island days when he was importing machines from Switzerland.

He had obtained exclusive distribution rights in North America for Simar Rototillers, and these machines used the two piece spring tines which were also used by Rototiller, Inc. when production began in Troy, NY about 1937 and can be seen on the Rototiller Model B1-3 made in Troy. (See Graphic E)

Graphic J - The Seaman Patent shows that there was still a demand for Spring Tines as late as 1940

Graphic G - 1949 Model T Rototiller offered alternative tine styles designed to accomplish other gardening tasks.

This notion of “turning under” various garden plant growth became known as “Power Composting.” Rototiller, Inc. had survived a few difficult years producing the one-wheeled “Home Gardener” until 1948 when declining sales forced the company to reinvent their product. At this point we begin to see tine styles change with the introduction of various “Blade” types designed to avoid “tangling” of green matter in the tine sets and to actively “turn under” this green plant material as a benefit to soil improvement.

Enter the Roto-Ette “Model t” (see Graphic G). Introduced in 1948, this tiller featured two wheels, rear mounted tines, simple gear and shaft transmission housed in a cast iron case and several options as to tine style. this product was offered at a reasonable $195.00 at your local Rototiller Inc. dealer. It was an immediate success. Dealers were ordering faster than the company could turn them out. and now dealers had accessories to offer their anxious customers. New in the tine department was the “Revolutionary new Roto-MILLER for Miracles of soil Improvement.”

Graphic H - Chopper Tines. Offered to Rototiller owners in the late 1950's and kept in production by Garden Way Mfg. as an alternative tine product.

Graphic I - Bolo Tines. The standard tine offering on all Tory Built tillers. They were capable of turning under standing corn stalks as long as the stalks were tender and green.

Graphic K - This DuFour Patent affirms the demand for a tine style that could meet the changing needs of tiller users for a product that could accomplish a range of tasks.

Graphic L - Roto-Millers were introduced about 1949050 to meet the demand for a tine that could do more than cultivate the soil. These were said to be able to turn under organic matter such as cover crops, for soil improvement.

The need for tine styles that could do more than just cultivate the soil was picking up steam. Gardeners were apparently getting more vocal about frustrations with tines that prematurely bent out of shape and could not bury plant residue. Plant material often would wind up around the tine set and had to be removed at the end of the row. Rototiller, Inc. responded to this need with the new Roto-Millers, and later with Chopper tines. (see Graphic H) But Garden Way Mfg. continued to offer and sell the old standby wire tines known as Pointed Pick tines and Cultivating tines. Later when Garden Way Mfg. succeeded the old Rototiller company, they developed the Bolo tine (see graphic I) as the standard tine option which could “bury standing corn stalks,” but they continued to offer and supply Pointed Pick and Cultivating tines to their Troy Bilt customers for many years after. (Garden Way Mfg. also supplied these and other parts to their now orphaned Rototiller, Inc. owners).

To conclude, we can see that tine geometry developed over the years from drawn round stock in the 3/8ths to 1⁄2 inch diameter which was heated and shaped into various designs. These products were usually made from an alloy of steel which could give them a “spring” effect creating a certain amount of “give” without bending the tine out of shape. (see graphics E,F,J and M) these were often referred to as “wire tines” and were very good at working in already cultivated and rocky soils.

Graphic M - Pointed Pick tines used by Rototiller, Inc. on models after WWII and also made available to Troy Built users until the late 1970's. Premature bending could be caused by improper heat treating and/or inappropriate grade of steel selected.

But soon demand from users called for a product which could do more as the notion of “Power Composting” became prevalent with gardeners. This would allow the rotary tiller to start in the spring with the task of turning under a green manure crop for soil nutrition and seed bed planting, then cultivate during the growing season as well as turn under weeds between rows, and finally in anticipation of winter, put the garden to bed by burying crop residue so a fall cover crop could be sown.

The idea of one particular tine design to do all this is a noble aspiration, and in my opinion, to this day no manufacturer has entirely succeeded. Rocky, loamy, sandy, or clay soils are simply not the same and a “one size fits all” solution just doesn’t work. Yet, even though over the years tiller users have had their “preferences or favorites” as the industry developed, still today the reality is that all tiller manufacturers offer only a “one size fits all” solution when it comes down to tine design.

Maybe that’s good enough for today’s home gardener; unless, of course, one wants to get out the old digging fork, or maybe if one’s garden is big enough, go back to the ox and plow.

Notes from the Author:

As a teenager, my family lived near Mr. Kelsey just outside the city limits of Troy. I would see him on a Saturday running his various machines, and testing prototype ideas. Often he would see me cutting the grass (with our 1935 Jacobsen Lawn Queen, no less) and ask me to come over for a few minutes to give him a hand. Needless to say, I was over there like a shot. It was always very exciting to see what he was up to. My family planted a garden every year and, of course, we had a troy Rototiller. My interest in gardening was formed early as a result of this.

Later in life I had the opportunity to work for Garden Way Mfg., successors to Rototiller, Inc. and this early experience proved to be very helpful on the job.

As a lifelong gardener and rotary tiller user I have experienced just about every tine design available. I have to say that I prefer to use the “wire tine” variety, in spite of the drawbacks. They work up the soil very gently for aeration and seed bed prep. When it comes to weeds, I either mow them first or pull them by hand, then till. adding organic matter is easy if it is shredded or composted first, then worked into the soil with ordinary tilling.

Finally, I need to express gratitude to my wife, Jane, for her editing skills with this story; my daughter-in-law, Kristina, for graphic design skills; and to my friend Allen B. Cluett (whose family were involved with Rototiller, Inc. from the very beginning) for sharing his knowledge, research and mechanical know-how in the development of this article.

Captions A, B, C, D, J, and K were supplied courtesy of the Archives of the Rensselaer County Historical Society, Troy, NY.